Pump Winterization

When outside temperatures start to fall below freezing you need to take measures to protect and winterize your pump. Each year, after the first frosts, we receive questions about why pump housings are being cracked open. The force caused by the expansion of frozen liquids is significant and can result in costly damages to your pump.

How to winterize a water pump?

Before you start any work on winterizing a pump it is important to follow standard safety procedures. Always make sure that the pump cannot be unintentionally switched on. Ensure that all drained liquid from the pump is carefully collected. Avoid any liquid spills which could lead to the creation of slippery surfaces or environmental pollution.- Centrifugal pumps: Drain the pump well by using the designated drainage plugs or covers. If the centrifugal pump is fitted with a vacuum system, then check additionally for liquids in the spaces in the float box and around the non-return valve. Not draining the pump correctly in case of frost can lead to cracked pump casings!

- Piston pumps: With our wellpoint dewatering pumps (piston pump principle), the pump housing is made up of several chambers. Ensure all the chambers including the cylinders, stone catcher and valve chambers are drained and emptied. Use the drain plugs and inspection covers for this. Let the pump run dry for a short time after draining in order to remove any remaining water and condensation.

- For pumps which will not be used for an extended period of time after draining we recommend to apply a preservative to the inside of the pump housing.

- Always make sure that the drain plugs and covers are closed again before starting the pumpset.

- Always consider draining or blowing through pipelines or hoses where possible.

Pump winterization for diesel driven units

In addition to the above mentioned measures to protect water pumps from freezing, the following additional tips apply to diesel driven pumps.- In the case of diesel engines, remember to periodically drain the reservoir of the fuel filter/water separator.

- Regularly monitor the condition of the battery. When the temperature drops, the battery's performance will significantly decrease while it has to work harder. Older batteries in particular can stop work without warning.

- If liquid has entered the containment tray of the casing, the lower compartment of the pump set should also be drained.

- Ensure that all fluids in the engine are suitable for use in sub-zero temperatures. This means that one should check whether or not engine coolant, engine oil, and also the fuel used can handle the local conditions.

- Do you have a diesel driven pump with SCR technology? Then keep in mind that the typical diesel exhaust fluid (AdBlue®) freezing point is -11° Celsius, 12 °Fahrenheit. Should you have any questions about this, please feel free to contact us.

Cold climate package for mobile pumps

Need to keep pumping when temperatures drop below freezing? Then use pumps that are factory equipped with a cold climate package. BBA Pumps offers different options to heat the interior of the unit. This significantly reduces the risk of pump damage or freezing issues during pumping. Contact us for more information or check the options here cold climate package for mobile pumps.Note: Always follow the instructions in the pump user manual for winterizing and regarding the cold climate pack. You can also contact one of our service employees for personal advice.

Cold Climate Packages

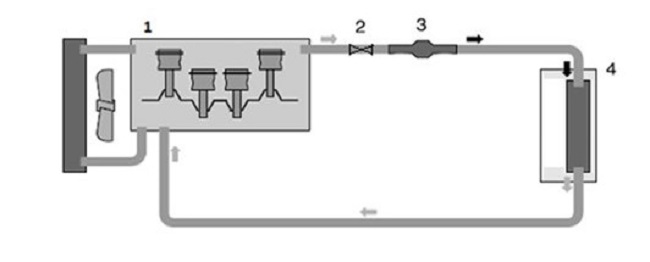

Optional Heating Systems for BA pumps powered by Hatz H50 engines 1. Natural Heating System. Choose this system to prevent the float tank from freezing during the pumping process.

1. Natural Heating System. Choose this system to prevent the float tank from freezing during the pumping process.The float tank of the BA pump is fitted with a heat exchanger which is connected to the engine water cooling system. When the engine is running, the water in the float tank is heated which prevents it freezing from the cold wind. When the outside temperature rises above freezing, the valve (2) can be closed in order to prevent damage to the vacuum system.

- Article number 93050110.

- This cannot prevent frost damage to the pump during standstill.

- The amount of refrigerant required differs from the manufacturer's specification in the engine manual.

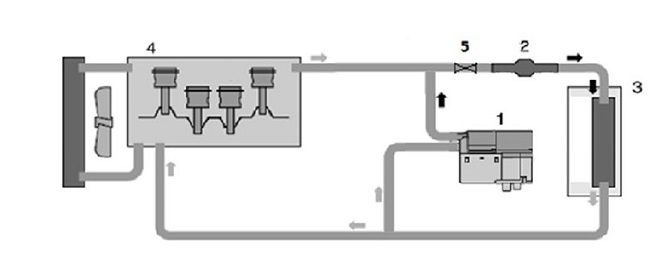

2. Electric Heating System. Choose this system to minimize the risk of freezing in cases where an external power supply is available.

2. Electric Heating System. Choose this system to minimize the risk of freezing in cases where an external power supply is available. An electric heating element heats the engine's cooling water and circulates the fluid through a heat exchanger in the BA pumps float tank. Even when at a standstill, the pump set remains heated thereby minimizing the risk of frost damage. When the outside temperature rises above freezing, the valve (5) can be closed to prevent damage to the vacuum system

- Article Number 115V 60Hz is 93050105 – 230V 50Hz is 93050100.

- A thermostat automatically switches the heater on / off.

- The amount of refrigerant required differs from the manufacturer's specification in the engine manual.

3. Webasto Heating System. Select this system to minimize the risk of freezing without depending on an external power supply.

3. Webasto Heating System. Select this system to minimize the risk of freezing without depending on an external power supply.The Webasto heater is equipped with its own diesel drive and circulation pump. The engines cooling water is heated and circulated via a heat exchanger in the BA pump float tank. Even when at a standstill, the pump set remains heated, reducing the risk of frost damage. When the outside temperature rises above freezing, the valve (5) is closed manually to prevent damage to the vacuum system.

- Article Number 93050120.

- Runs on diesel fuel that compliant with the EN590 standard.

- A thermostat automatically switches the heater on / off.

- The amount of refrigerant required differs from the manufacturer's specification in the engine manual.